Unser Motto

All previous screen and stencil cleaning systems on the market are known to have a fundamental, huge problem:

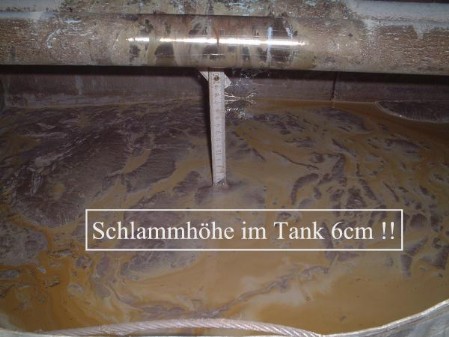

the continuous silting of the tank> the result is increasingly poor cleaning results over time.

Tank cleaning is very laborious, time-consuming and also very dangerous to health (solvent vapors) for the employees concerned.

Even with thorough tank cleaning, a certain amount of sludge deposits always remains in the corners, edges and inaccessible places in the tank and the supply lines to the nozzle assembly, i.e. even with a refill you will have contaminated medium again.

In addition, the suction lines are usually installed very low in the tank and therefore always suck in the deposits first.

To solve this problem we have developed the perfect solution:

Screen and stencil cleaning systems without tank, but with a docking device for standard barrels (58 and 200l). USE PROTECTION NO 20.2014.000.698.9

This ingenious system offers the following advantages:

Lightning fast solvent change without tools and direct contact with the solvent!

Optimal cleaning results again after changing the drum, as the solvent is absolutely free of contamination!

all sludge deposits are in the barrel and can be disposed of with it!

extremely long service life of the cleaner, as the suction is not located at the bottom of the barrel> no "sludge suction" when cleaning!

All screen and stencil cleaning systems developed by us have separate washing and drying chambers for the following reason:

The essential energy savings of the two-chamber technology is based on the fact that the surface wetted with water or cleaning agent is essentially reduced to the screen surface (plus an unavoidable water entry from the spray adapter) in the two-chamber process approximately proportional to the wetted surfaces. The wetted surface ratio of one-chamber technology to two-chamber technology is between 4 and 6, depending on the model.